Earlier in the year as we were looking to go into production we did a thorough FMEA (Failure Modes and Effects Analysis) on every component and identified some minor issues with the Handle latch mechanism that we weren't quite happy with. We had developed a complex mechanism that allowed golfers to "set and forget" their preferred handle height/angle using a bespoke Divot tool that doubled as a spanner.

The mechanism worked well in so far as it retained the set position and returned to its vertical stowed position regardless of the set angle. The FMEA identified some minor flex in the handle which we felt could be exacerbated if an umbrella is attached on a windy day. We quickly ruled out adding leg struts to provide rigidity as this meant more parts and more assembly when deploying the Bag. It went against our design philosophy.

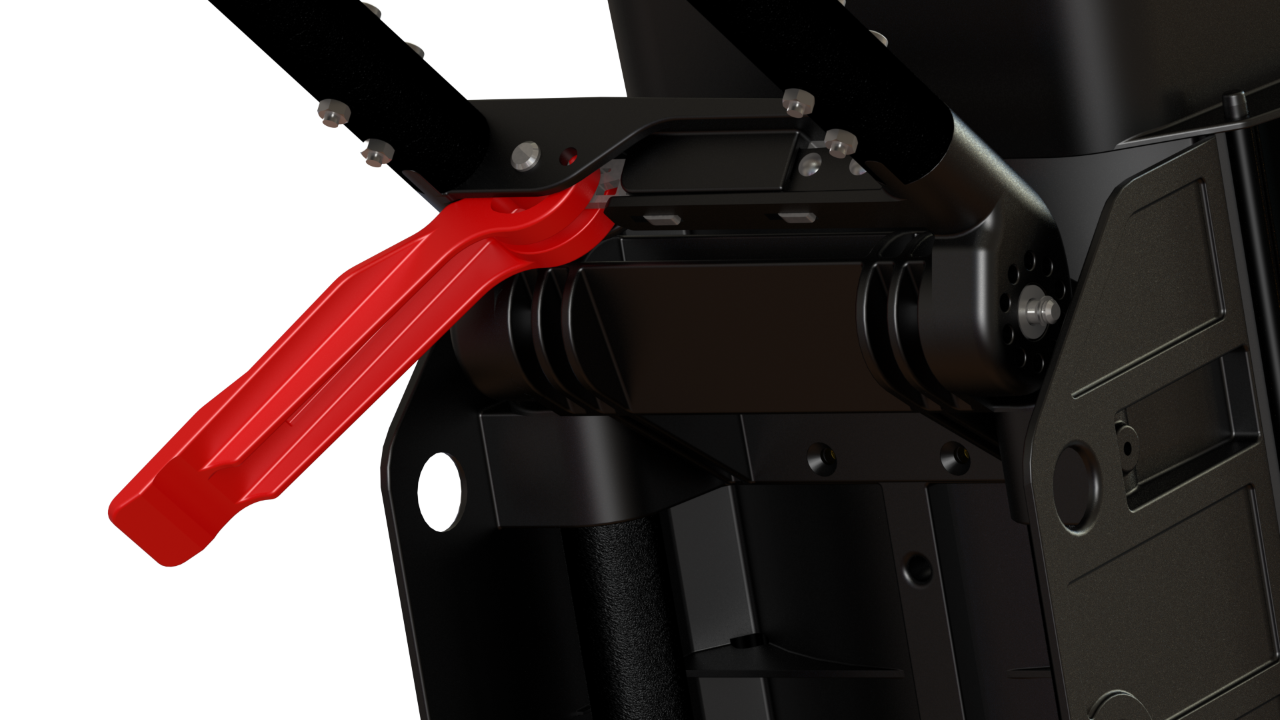

I'm pleased to say that after months of brainstorming, design work, porotypes and testing we have landed on a new design which ticks all our boxes. Its offset from the latch mechanism, sits behind the handle so is hidden when stowed away, is easy to use when changing handle heights/ angle and is strong.

We went through several teeth designs and configurations before settling on a solution and whilst the glass filled nylon teeth passed all our testing we've added metal teeth to add even more strength. And it just looks cooler!